Author

Fanny Yang

Fanny is Environmental Health and Safety Engineer, leading ESG projects and sustaining ISO systems. She has been working on sustainability projects with her team in NXP’s facility in Kaohsiung, Taiwan.

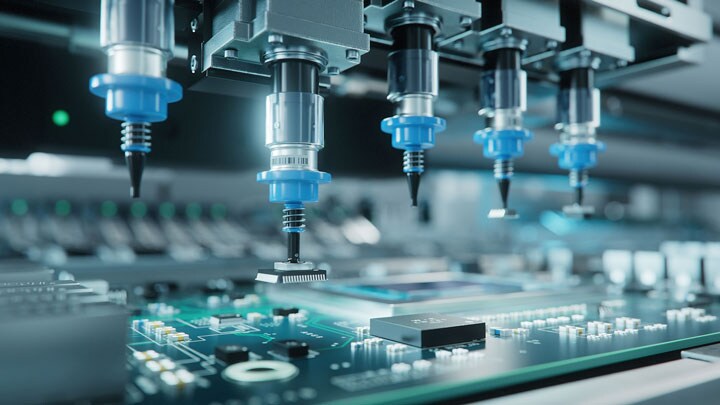

Imagine a world where waste is not discarded but becomes a catalyst for innovation and sustainability. At NXP’s facility in Kaohsiung, Taiwan, 120 tons of molding scrap waste is transformed annually into eco-friendly resources - reducing CO2 emissions and pollution. It's one example of how NXP is implementing innovative practices to create a more sustainable future.

The semiconductor industry is a critical driver of innovation for sustainability. The potential for energy optimization through manufacturing, processing and waste incineration processes is significant. NXP is taking bold action to counteract this impact. We are committed to reducing our greenhouse gas emissions by 55% by 2030 and achieving carbon neutrality by 2035. Let's look at how NXP is using proactive measures to reach these objectives and lessen our environmental footprint.

What if we could prevent tons of waste from entering the environment every year? NXP has taken a pioneering step in Kaohsiung by transforming molding scrap waste into valuable resources. Through innovative recycling methods, we divert 120 tons of waste from the environment each year. This proactive approach not only mitigates waste but also lessens the reliance on energy-intensive raw material mining - cutting CO2 emissions at the source.

A key player in molding scrap waste is silica , which gets a second life through innovative repurposing in numerous fields. It’s clear, plastic-like appearance, paired with its feather-light and super-tough properties, makes it perfect for a variety of uses. Recycled silica doesn't just stop there — it supercharges green building materials, boosting the strength and durability of rubber. And in eco-friendly coatings, it offers superior abrasion resistance.

Silica can also be converted to an alternative for plastic. This reduces reliance on petroleum and bypasses the energy-heavy recycling of traditional plastics. NXP is working with Transcene Corp , a Taiwanese company in resource recycling, to repurpose silica for plastic at their manufacturing plant. The result? Less waste and more resources to contribute to a closed-loop economy.

By breathing new life into old waste, NXP is cutting its environmental impact. We’re reaching across industries to collaborate with other eco-minded companies for the good of the planet. We currently transform our waste for other uses, aiming to integrate it into our future manufacturing processes.

By setting new standards for responsible manufacturing across our supply chain and beyond, we're paving the way for an eco-friendly tomorrow.

Environmental Health Safety Systems, NXP Semiconductors

Fanny is Environmental Health and Safety Engineer, leading ESG projects and sustaining ISO systems. She has been working on sustainability projects with her team in NXP’s facility in Kaohsiung, Taiwan.

Dec 6, 2024

by Cosmin Adam

Dec 6, 2024

Dec 6, 2024

by Tony Khaw